Quality

Quality is central to everything we do at Hudson Precision. It isn't just a certificate or a title on the door to a department; quality is infused through our facility and our people.

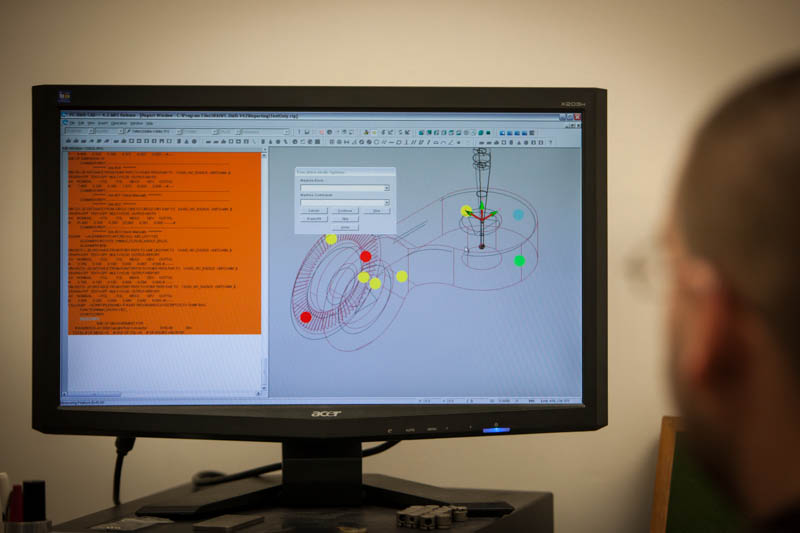

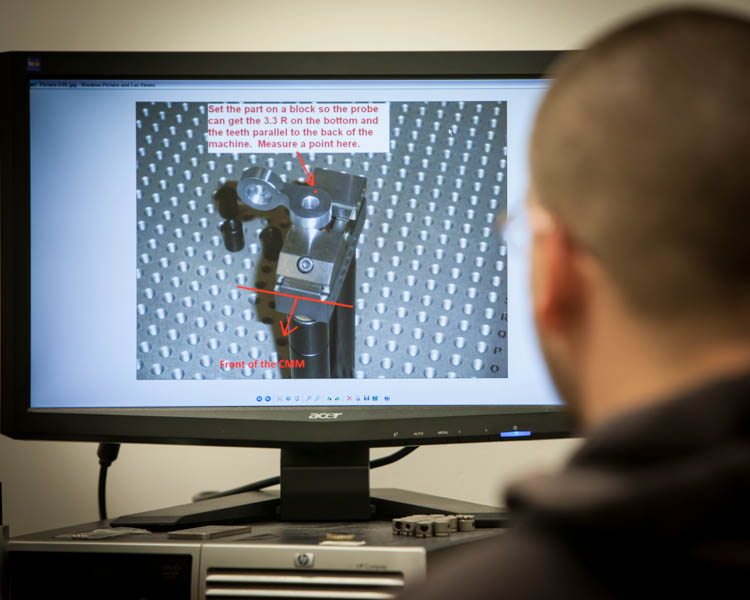

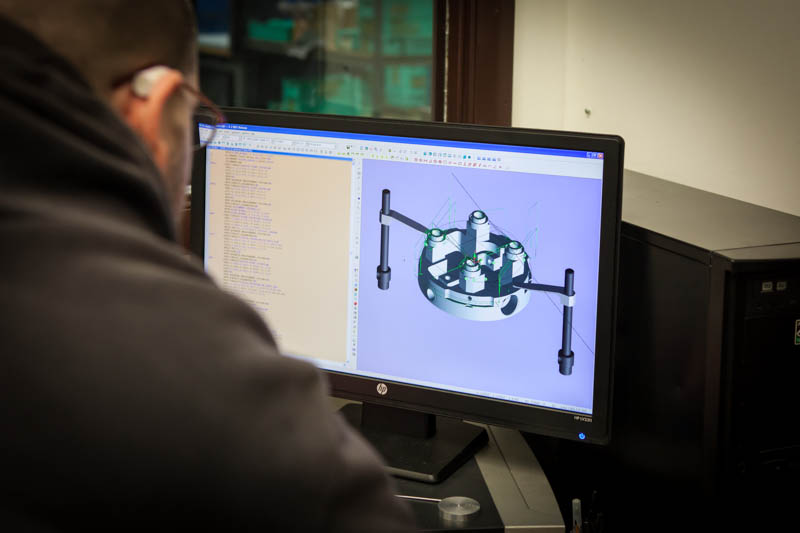

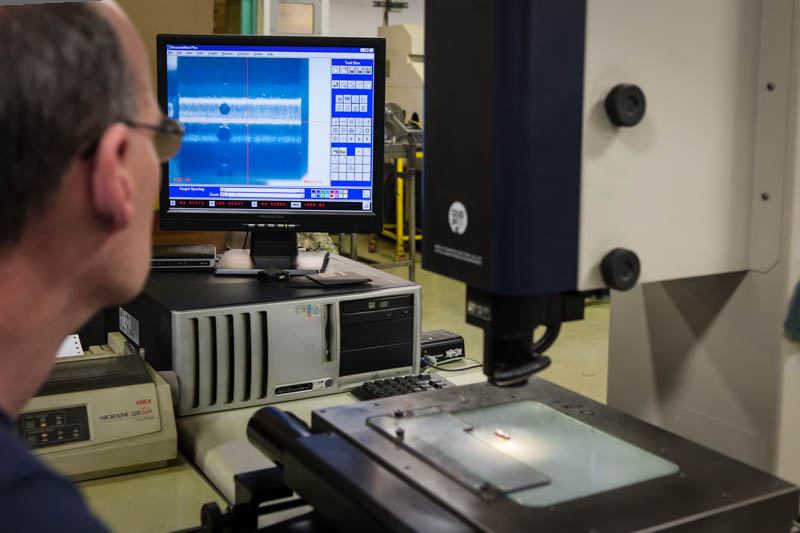

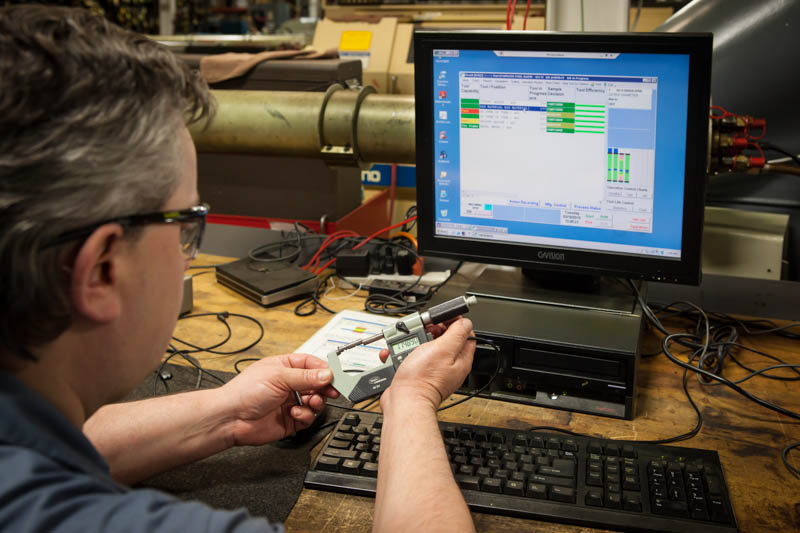

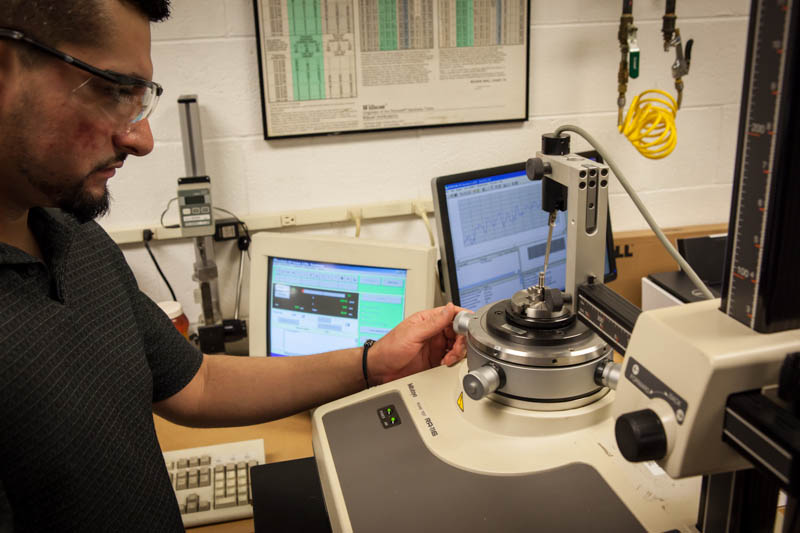

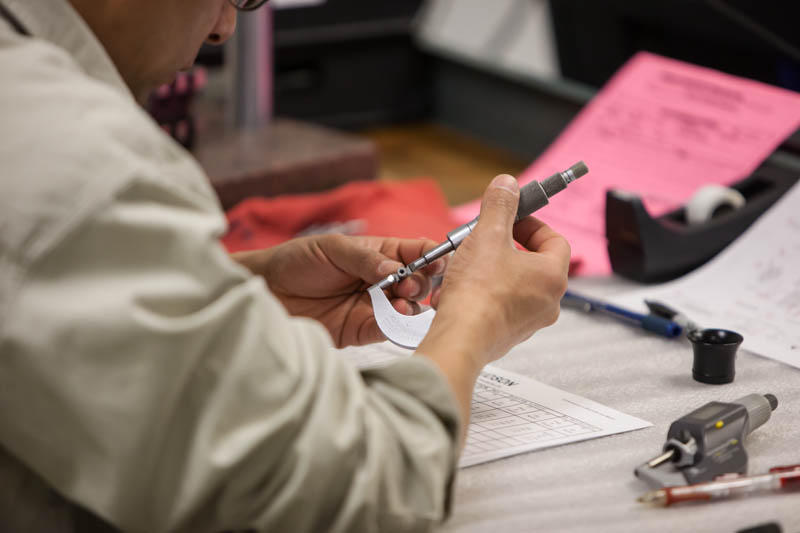

Our quality assurance department maintains a well-documented quality history on performance. All inspection equipment and gages are calibrated and certified at regular intervals to assure the highest accuracy of inspection results.

Our engineers develop process drawings to incorporate pre-control tolerancing, which insures that quality is not left to chance.

First article inspection is performed on all primary and secondary operations to ensure part quality and machine capability. Your parts are constantly checked during production operations to meet the demanding reputation we have achieved over our hundred-plus years of leadership.

Final part inspections are performed and certified to Mil-Standard or the customer-specified quality level required.

Our entire operation is ISO certified to 9001:2015 standards

Hudson Precision Products Quality Systems

Watch this slide show to learn more about Hudson Precision Products' fully integrated quality system.

The slides advance automatically or you can control them directly with play/pause button or the slide numbers.

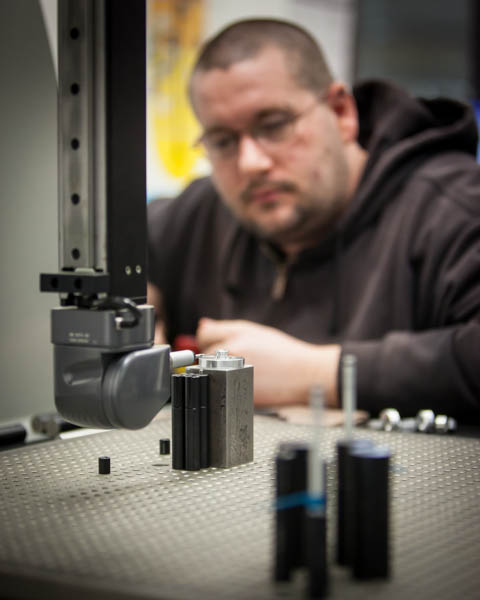

Training For Quality

At Hudson Precision Products, over 100 years' proven performance isn't enough. Your succes relies on our quality.

At Hudson Precision Products, over 100 years' proven performance isn't enough. Your succes relies on our quality.

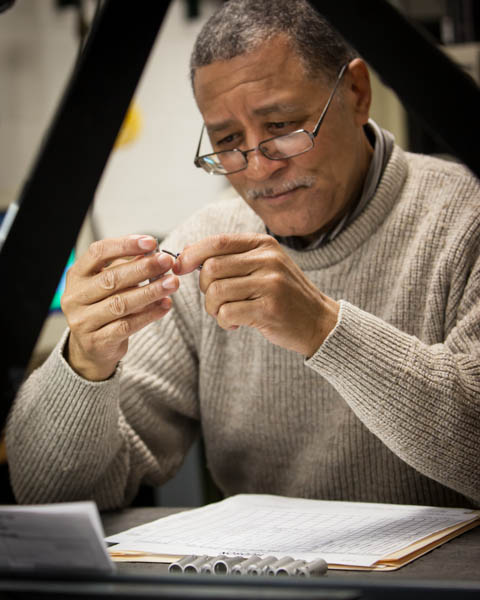

You can depend on our staff with an average experience level of over 20 years per person. We combine factory training on new techniques, software, and equipment, with ongoing in-house training in our quest for continuous improvement.

Perpetuation of the company and our legacy of quality is important, too. Young new employees inject our company with energy and enthusiasm that keeps our spirit fresh and vibrant. We work with a number of local schools to nurture a young and well-trained talent pool. We actively participate in Chicago area educational commitees to make sure we have the help we need, while providing a great working environment for our community members.

Today's manufacturing environment is more exciting than every, loaded with high-tech equipment and abundent opportunities. Hudson Precision Products participates in educational development on a state and national level as well as our local programs. Through the PMPA and the TMA Education Foundation, Hudson works to sustain and build new programs for a rich, hands-on educational experience for future generations of manufacturing workers.

It is our conviction that our success over generations traces back to education. We have dedicated classrooms and required education programs for all employees. We offer opportunities for continuing education through our trade associations, local colleges and universities. Success comes through people.